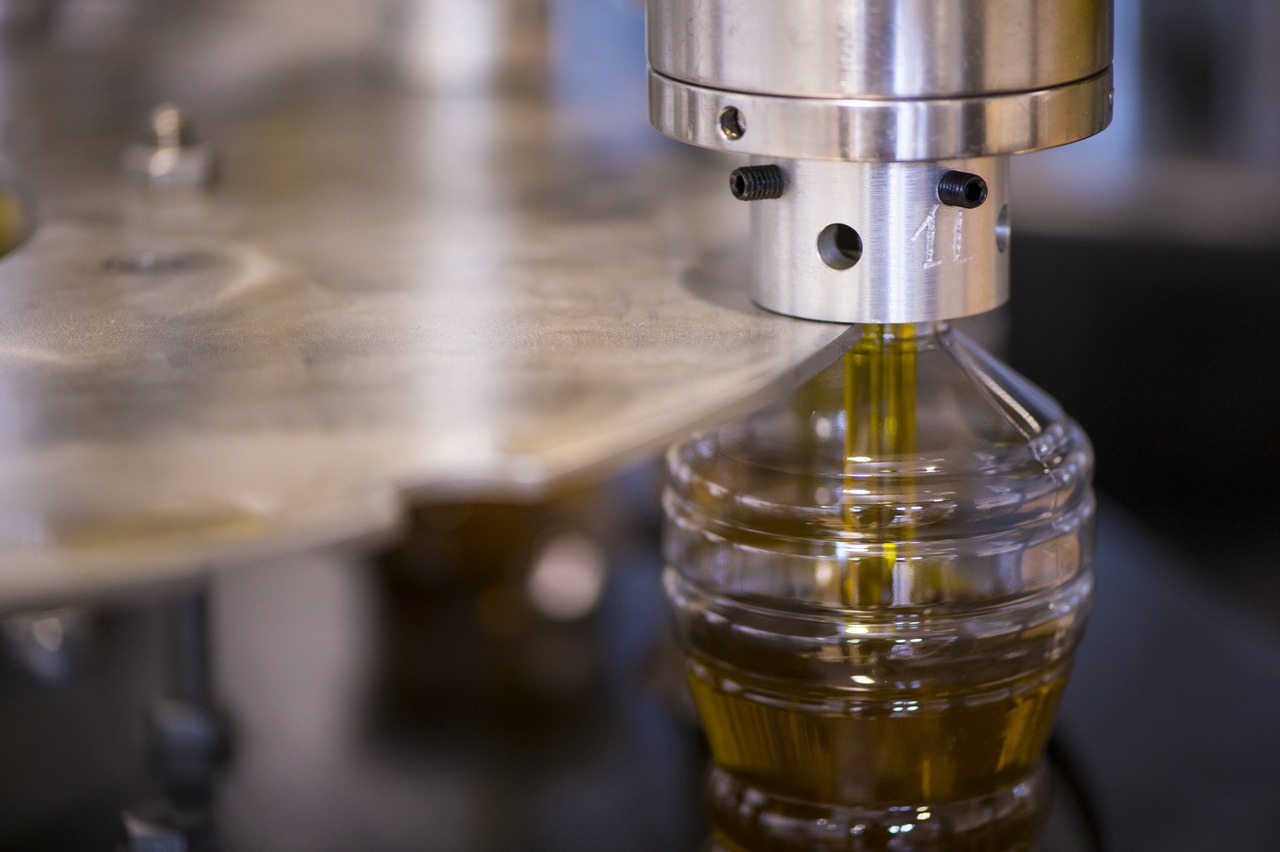

Biozevtika provides contractual services for the production of CO2 extracts from the customer’s raw materials. When working according to the standard contract scheme, the customer receives both the entire CO2 extract, which is generated from the raw materials given to us as part of the toll scheme, as well as the meal on the basis of the work result. You can read more about the meal, its properties and application perspectives in an overview article at this link. About CO2 extracts on this.

In the case of commissioned work, the customer only pays for the physical work involved in preparing the raw material and obtaining an extract – these prices are fixed prices and do not depend on the raw material costs.

Working on a contract basis can be interesting for companies that own large quantities of their own raw materials and have developed distribution channels – in this case, broad perspectives open up for the sale of CO2 extracts (or complex products based on them), such as functional mixtures on dry carriers) and meal.

Contract work can also be interesting for companies that have access to rare and unique raw materials – in such cases, processing the raw materials into extract and meal with subsequent sale of both often leads to a better marginal result than the usual wholesale or retail trade.

In addition to the usual drafting of contracts, we also provide services for the “explosion” of the customer’s raw materials in order to ensure an optimal nutrient yield when these raw materials are used later in the end product. The most typical case for such applications are functional tonic drinks that require quick brewing and a tonic effect that is clearly noticeable to the user, which is achieved precisely by the higher (2-3 times) yield of substances that are active in this way in the drink the “exploded” raw material compared to conventional raw materials.

We can also specifically empty the customer’s raw materials and reduce his spice aromas to the level desired by the customer. Most often, such a need arises from manufacturers of dishes based on recipes of Southeast Asian cuisine, whose original recipes are too spicey for the domestic consumer, but which significantly lose their characteristics with a mechanical decrease in the amount of spices they contain.